Super User

| Floor | Formal Name | Features | Layouts | Max Capacity | Assignable Area (Sq. Meter.) | ||

| 2 |

Exibition Laboratory of Petrology |

Lighting Systerm – Fluorescent; Storage- rock samples, maps; Following equipments: |

Lab | 30 | 110 | ||

|

Figure 1: Rock samples |

Figure 2: Rock samples |

Figure 3: Rock samples |

|||||

|

Figure 4: Rock samples |

Figure 5: Rock samples |

Figure 6: Rock samples |

|||||

GE Labs Overview

All Geological Engineering labs are mainly used for teaching undergraduate GE courses whereas three of them, Seismic Data Processing Laboratory, Geophysical Laboratory and Petrology Laboratory, are also used for faculty and student research.

The GE Program operates 6 teaching laboratories:

- Exhibition Laboratory of Petrology,

- Sample Processing Laboratory,

- Petrology Laboratory,

- PVU-Schlumberger Office

- Seismic Data Processing Laboratory

- Geophysics Laboratory.

Name: PHAN NGOC HOANG

Institutet: Ba Ria-Vung Tau University

Rank: Adjuct Faculty

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Telephone:

Fax:

Research Interests: System Analysis, Management and Information Processing

Address: Fundamental Science, PetroVietnam University, 762 Cach Mang Thang Tam street, Long Toan ward, Ba Ria city, Ba Ria- Vung Tau, Viet Nam.

Degree

| Degree | Field | Institution | Year |

| Ph.D. | System Analysis, Management and Information Processing | Tomsk National Research Polytechnic University, Russian Federation | 2014 |

| B.Sc. | Information Systems and Technology | Irkutsk State Technical University, Russian Federation | 2008 |

Rank

| Rank | Month-Year |

| Lecturer | 2020 - Present |

Own Thesis

| Title | Type | Institution | Year |

| PhD | Tomsk National Research Polytechnic University, Russian Federation | 2014 | |

| B.Sc. | Irkutsk State Technical University, Russian Federation | 2008 |

Experience (Academic)

| Institution | Rank, Title | Year/Period | FT/PT |

| PetroVietnam University | Lecturer | 2020 - Present | PT |

| Ba Ria-Vung Tau University | Dean of Faculty of Technology Engineering – Hitech Agriculture; | 2014 - Present | FT |

| Tomsk Polytechnic University, Russian Federation |

+ PhD + AI Developer |

2010-2014 | PT |

| PetroVietnam University | Researcher | 2014 – 2016 | FT |

Courses

| Institution | Course No. | Course Name | Type | Level | Times | Last Time |

| PetroVietnam University | INC31301 | Foundations in Engineering 2 | Academic | Undergraduate | 1-5 | 2020-Present |

Conference

| No. | Information |

| 1 | Phan Ngoc Hoang, Future Job Market in the Fourth Industrial Revolution, 17th International Symposium on Management (INSYMA 2020) Part of Series: Advances and Management Research, Vol. 115, Atlantis Press SARL, pp. 147-151 (ISI-CPCI), ISSN 2352-5428, 2020. |

Journal

| No. | Information |

| 1 | Phan Ngoc Hoang, Development English Pronunciation Practicing System Based on Speech Recognition, Context-Aware Systems and Applications, LNICST, Vol 298, Springer, pp. 157–165 (SCOPUS), ISSN 1867-8211, 2019. DOI: 10.1007/978-3-030-34365-1_12 |

| 2 | Phan Ngoc Hoang, Context-aware Hand Poses Classifying on Images and Video-sequences using a Combination of Wavelet Transform, PCA and Neural Networks, Journal EAI Endorsed Transaction on Context-aware Systems and Applications, EAI, EUDL, Issue 12, Vol. 4, e2, ISSN 2409-0026, 2017. http://dx.doi.org/10.4108/eai.6-7-2017.152758 |

| 3 | Phan Ngoc Hoang, Context-aware Handwritten and Optical Character Recognition Using a Combination of Wavelet transform, PCA and Neural Networks, Context-Aware Systems and Applications, LNICST, Vol 165, Springer, pp. 254–263 (SCOPUS), ISSN 1867-8211, 2016. http://dx.doi.org/10.1007/978-3-319-29236-6_25 |

Degree

| Degree | Field | Institution | Year |

| B.Sc | Information Technology | Ton Duc Thang University | September, 2009 |

Experience (non-Academic)

| Organization | Designation | Year/Period |

| Petrovietnam University | Acting Director | Jan 2020 - Present |

| Petrovietnam University | IT Engineer | Nov 2011 – Dec 2019 |

| PA Infotel | Software Developer | 2009 - 2011 |

Courses

| Institution | Course No. | Course Name | Type | Level | Times | Last Time |

| Petrovietnam University | - | Basic Programming Lab - (C/C++ Lab) | Academic | Undergraduate | 2018 - Present | |

| Petrovietnam University | - | Fundamental Science - Python programming (Lab) | Academic | Undergraduate | 2018 - Present |

Software Skills

| Type | Description |

| Languages | Vietnamese (native), English (Intermediate) |

| Programming IDE | Visual Studio, PyCharm, Netbean, Power BI, Power Automate |

Degree

| Degree | Field | Institution | Year |

| PhD | Pipelines and Storage Construction and Repair | Gubkin University, Russia | September, 2018 |

| MSc | Pipelines and Storage Construction and Repair | Gubkin University, Russia | June, 2015 |

| BSc | Mechanical Engineering | Belarusian National Technical University | June, 2010 |

Rank

| Rank | Month-Year |

| Lecturer | 2019 - Present |

| Laboratorian | 2011 – 2018 |

| Mechanical Engineer | 2010-2011 |

Own Thesis

| Title | Type | Institution | Year |

| Разработка методов повышения несущей способности оснований РВС в гидрогеологических условиях Вьетнама | PhD | Gubkin University, Russia | 2015 - 2018 |

| Исследование возможности применения грунтовых модулей ГП-1500 при сооружении участка технологического проезда на слабом грунте для строительства газопровода в проекте ПМ3-КаМау во Вьетнаме | MSc | Gubkin University, Russia | 2013 - 2015 |

Experiences (Academic)

| Institution | Designation | Year/Period |

| Petrovietnam University | Head of Department of External Relations, Science and Technology | September 2019 - Present |

| Petrovietnam University | Lecturer | February 2019 – September 2019 |

| Petrovietnam University | Laboratorian | November 2011 – February 2019 |

Experiences (non-Academic)

| Organization | Designation | Year/Period |

| National Research Institute of Mechanical Engineering | Mechanical Engineer |

Septermber 2010 – November 2011 |

Courses

| Institution | Course No. | Course Name | Type | Level | Times | Last Time |

| Petrovietnam University | MEC32303 | Mechanical Theory | Academic | Graduate | - | 2019-Present |

| Petrovietnam University | PHY21101LAB PHY21102LAB |

Physics Experiments | Academic | Graduate | - | 2011-2019 |

Journal

| no. | Information |

| 1 | Nguyen Phan Anh, Tuyen Vo, Khanh Dien Le, Thanh Nam Nguyen ”A Measure of Optimization of Technological Parameters to Improve the Formability of Aluminum Sheet a 1050 H14 by SPIF Technology”,Key Engineering Materials, Vol. 863, p. 51-58, 2020, https://doi.org/10.4028/www.scientific.net/KEM.863.51 |

| 2 | Tuyen Vo, Thanh Nam Nguyen, Phan Anh Nguyen, Khanh Dien Le, Tan Ken Nguyen, Trung Le Tran “A Measure of Optimization of Technological Parameters to Improve the Formability of Stainless Steel Sheet SUS 304 by SPIF Technology”,Key Engineering Materials Vol. 863, p. 59-66, 2020, https://doi.org/10.4028/www.scientific.net/KEM.863.59 |

| 3 | Le Van Sy, Nguyen Phan Anh, Vu Minh Hung, Nguyen Ha Trung “Studying and evaluating the use of demineralised water in Thermal power plants”,PetroVietnam Journal, Vol. 3, 2020 (in Vietnamese), 2020, http://www.tapchidaukhi.vn/BookDetail/nghien-cuu-danh-gia-viec-su-dung-nuoc-khu-khoang-tai-cac-nha-may-nhiet-dien-4asjvkzBHUC4tT_2x8_SYg.html |

| 4 | Nguyen P.A., Salnikov A.P. “Practical application and numerical modelling of vacuum consolidation of the basement of a vertical steel tank in building construction project of power plant Ca Mau in Viet Nam”, Pipeline transport: Theory and Practice, Vol. 5, p. 46-52 (in Russian), 2017 |

| 5 | Vaxiliev G.G., Nguyen P.A. “Numerical modelling of soft soil stabilized by vertical drains in building construction project of power plant Ca Mau in Viet Nam”, Proceedings of Gubkin Russian State University of Oil and Gas, Vol. 2, p. 115-124 (in Russian), 2017 |

| 6 | Vaxiliev G.G., Nguyen P.A. “Numerical model for thermal consolidation of the basement of a vertical steel tank on saturated soft soil”, Transport and storage of oil products and hydrocarbons, Vol. 1, p. 5-8 (in Russian), 2017 |

| 7 | Vaxiliev G.G., Nguyen P.A. “Ensuring the sustainability of oil and gas installations and structures under engineering geological and hydro-geological conditions in Vietnam”, Pipeline transport: Theory and Practice, Vol. 5, p. 41-43 (in Russian), 2016 |

Research Projects

| Code No. | Title | Institution | Position | Year |

|

01/DIEN/ĐHDK /2018/KHCN |

Studying and evaluating the use of demineralised water in Thermal power plants | Vietnam Oil and gas Group | Col. | 2018-2019 |

| GV1913 | Measure of optimization of technological parameters to improve the formability of steel by SPIF technology | Petrovietnam University | PI | 2019 |

| GV2007 | Investigation on the role of calcium on microstructure and pitting corrosion resistance of Mg-5Al-4Sn-based alloys | Petrovietnam University | PI | 2020-present |

|

01/KTQL(PVU) /2020/KHCN |

Preparation of Lectures in Petroleum Exploration and Production, Petrochemical Refining, Oil Processing and Electricity for staffs of Vietnam Oil and Gas Group (1st Stage) | Vietnam Oil and gas Group | Col. | 3/2020-Present |

| Chemical Engineering Program | Formal Name | Courses | Layouts | Max Capacity | Assignable Area (Sq. m.) | |

| Mechanics of Fluid Lab | Mechanics of Fluid Lab | Lab | 18 | 50 | ||

|

Entrance |

Computer controlled fluid friction in pipes unit |

|||||

|

Bernoulli’s theorem demonstration unit |

Osborne- Reynolds demonstration unit |

|||||

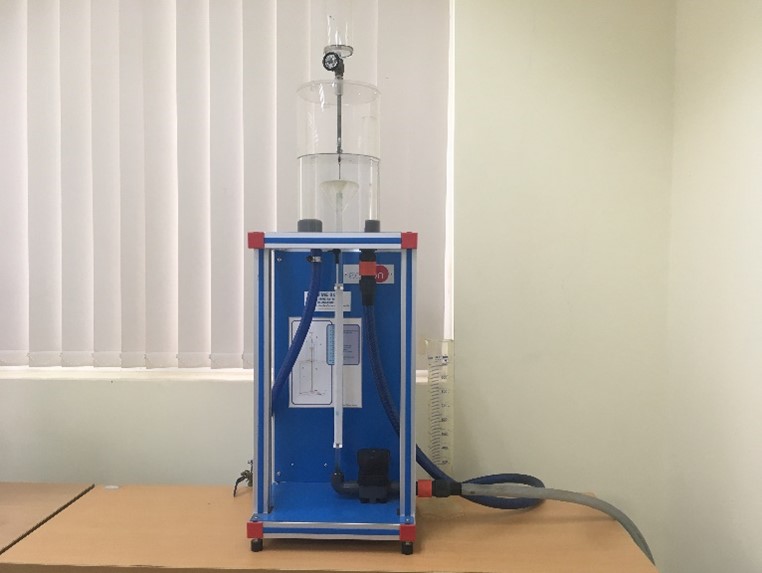

| Petroleum Engineering Program | Formal Name | Courses | Layouts | Max Capacity | Assignable Area (Sq. m.) | |

| Materials and Mechanical Lab | Strength of Materials | Lab | 8 | 60 | ||

|

Entrance |

Lab layout |

|||||

|

Document Cabinet |

Tinius Olsen’s hydraulic Universal Testing Machine Model 300SL |

|||||

|

Tinius Olsen's pendulum impact tester |

Torsion Testing Machine |

|||||

|

The Helios 350-V projector |

The OBLF Analyzer |

|||||

| Petroleum/Chemical Engineering Program | Formal Name | Courses | Layouts | Max Capacity | Assignable Area (Sq. m.) | |

| Electricity -Electronics Lab | Electricity -Electronics; Electrical Circuit Analysis | Lab | 24 | 60 | ||

|

Entrance |

Lab layout |

|||||

|

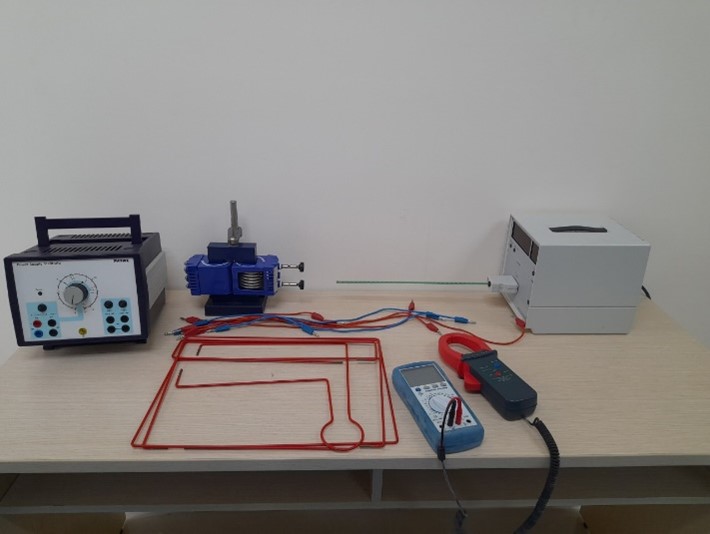

Power Supply, Data Acquisition Interface; Three phase circuit; 1-3 phase Transformers |

AC Motor/Generator, DC Motor/Generator, R-L-C Loads |

|||||

|

Power Supply, Three phase circuit; Data Acquisition Interface; R-L-C Loads |

Electronic Devices, Osiloscop, Function Generators |

|||||

| PE/CE/GE Program | Formal Name | Courses | Layouts | Max Capacity | Assignable Area (Sq. m.) | |

| General Physics Lab |

General Physics Lab 1 |

Lab | 40 | 140 | ||

|

Entrance |

Lab layout |

|||||

|

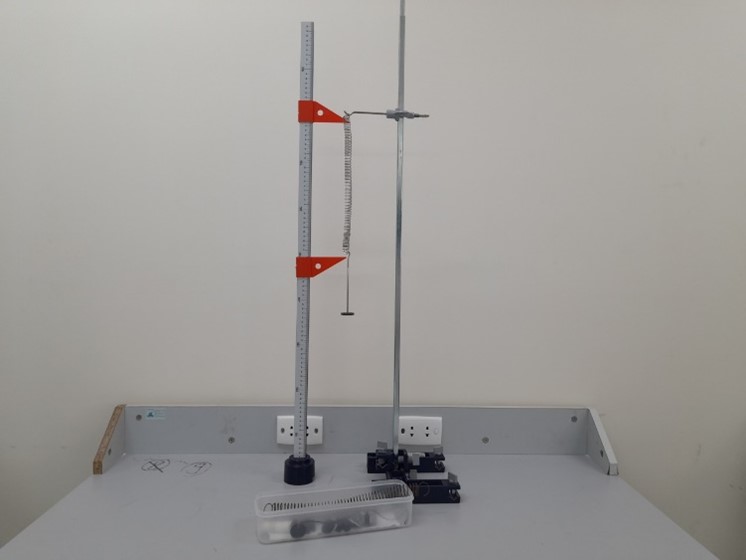

Measurement of length |

Measurement of volume and density |

|||||

|

Inertia moment of rigid bodies |

Hooke’s law |

|||||

|

Simulated experiment of viscosity |

Simulated experiment of ideal gases |

|||||

|

Simulated experiment of Bernoulli’s equation |

Transformer |

|||||

|

Magnetic field outside straight conductors |

Specific charge of the electron e/m |

|||||

|

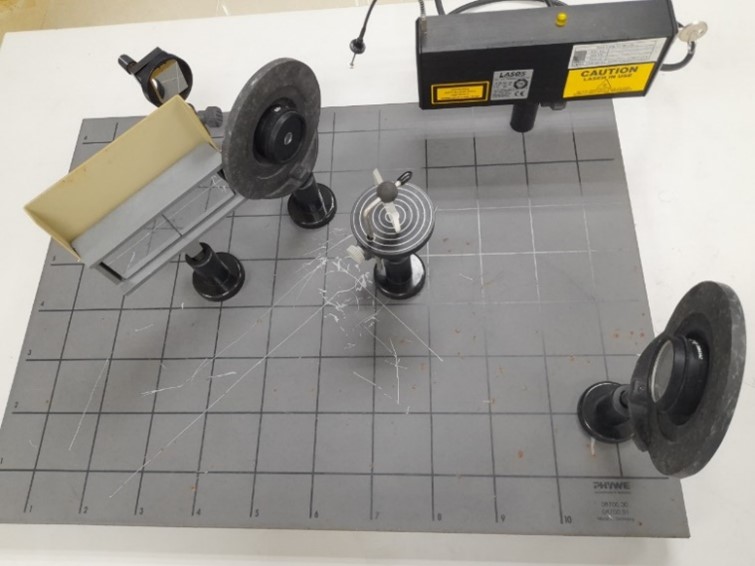

RLC measuring bridge |

Newton’s ring |

|||||

|

Interference by Fresnel’s mirror and biprism |

Polarization of light |

|||||

Name: Le Van Sy

Rank: Lecturer

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.;

Telephone: (+8254) 372 1979

Fax: (254) 3.733579

Research Interests:

Address: Petrovietnam University, 762 Cach Mang Thang Tam street, Long Toan Ward, Ba Ria City, Vietnam.

Degree

| Degree | Field | Institution | Year |

| Post-doc (VEF scholar) | Petroleum-Mechanical Engineering | The University of Tulsa, USA | 2012 |

| Ph.D. | Industrial Engineering and Manufacturing | University of Padua, Italy | 2010 |

| M.Sc. | Mechanical Engineering | University of Ulsan (UOU), South Korea | 2007 |

| B.Sc. | Mechanical Engineering | Ho Chi Minh university of Techology (HCMUT), Vietnam | 2003 |

Societies

| Name | Country | Membership | Year/Period |

| Scientific Committee PetroVietnam | Vietnam | Member | 2017 - Now |

| Offshore Structure and Technology consortium | Vietnam | Member | 2015 - Now |

Experiences (Academic)

| Institution | Designation | Year/Period | FT/PT |

| Petrovietnam University | Vice Rector, Lecturer | 2017 – 2021 | FT |

| Petrovietnam University | Director, Advanced Training Center, Lecturer | 2014 – 2017 | FT |

| Petrovietnam University | Lecturer | 2011 – 2013 | FT |

| PetroVietnam Project Board | Academic staff | 2010 - 2011 | FT |

| Ho Chi Minh university of Techology (HCMUT) | Teaching Assistant | 2004 - 2005 | FT |

Honors and Awards

| Name | Details | Year |

| The Best Paper Award | ICACE | 2019 |

| Gold Medal of Techmart 2018 | Techmart | 2018 |

| VEF scholar fellowship | VEF | 2012-2013 |

Conferences & Journals

| no. | Information |

| 1 | Van Sy Le (et al.), Positioning and Trajectory Tracking for Caterpillar Vehicles in Unknown Environment. International Journal of Control, Automation and Systems, 2020. SCIE index (IF = 2.181) |

| 2 | DaeHwan Kim, Le Van Sy. A MIMO Robust Servo Controller for a Two Wheeled Automated Guided Vehicles Using a Differential Operator. 2020 KSPSE Spring Conference, 2020. (Scopus). |

| 3 | Seungmin Kim, Le Van Sy. Reliability Centered Maintenance for Large Volume of Pumping Process: A Case Study, 2nd International Conference on Advanced Convergence Engineering (ICACE) 2019. (K-SCI index). |

| 4 | Le Van Sy, Dang Thuc Van, Selection of an optimizing inlet angle for the gas-liquid cylindrical cyclone separator on hydrokinetic behavior, 2nd International Conference on Advanced Convergence Engineering (ICACE) 2019. (K-SCI index) |

| 5 | Le Van Sy (et. al.) Design of a lightweight magnetizer to enable a portable circumferential MFL system, IEEE Transactions on Magnetics. (SCI index, IF=1.1467). |

| 6 | Le Van Sy, (et. al.) Highly Sensitive Planar Hall Magnetoresistive Sensor for Magnetic Flux Leakage Pipeline Inspection, IEEE Transactions on Magnetics. (SCI index, IF=1.1467). |

| 7 | Le Van Sy, Influence of Inlet angle on flow behavior and performance of GLCC, Particulate Science and Technology, 2017 (SCIE index, IF=0.523). |

| 8 | Le Van Sy, Pham Thi Minh Hue, implement a Modified Viscoplasticity Based on Overstress Model into Numerical Simulation of the Incremental Sheet Forming Process, Advanced Engineering – Theory and Applications, 2016. (ISI index) |

| 9 | Le Van Sy, Nguyen Thanh Nam, Hot Incremental Forming Of Magnesium And Aluminum Alloy Sheets By Using Direct Heating System. Journal of Engineering Manufacturing, 2013 (SCI index, IF=1.982) |

| 10 | Le Van Sy, Nguyen Thanh Nam, Effect of Strain Rate And Temperature On Formability Of Warm-Incremental Forming Process With Magnesium Alloy Sheet AZ31, Journal of Manufacturing Technology Research. (Scopus index) |

| 11 | Le Van Sy, Calibrating A Fracture Criterion For A Numerical Simulation Of Warm-Incremental Forming Process. AETA 2015: Recent Advances in Electrical Engineering and Related Sciences, Volume 371 of the series Lecture Notes in Electrical Engineering, pp 857-867. (ISI index) |

| 12 | Le V. Sy, Nguyen T. Nam. Numerical Simulation Of Incremental Forming Process For Polymer Sheets. International Journal of Modelling and Simulation, Vol 32-4, pp 265-272. (Scopus index). |

| 13 | V. S. Le , A. Ghiotti, G. Lucchetta, Preliminary Studies on Single Point Incremental Forming for Thermoplastic Materials, International Journal of Material Forming, Vol. 1, Issue 1, pp 1179-1182, (SCIE index). |

Professional Development Activites

| No. | Description |

| 1 | Member of National Scientific Committee in Mechanical Engineering, Fluid Mechanics |

| 2 | Reviewer: International journal of Advances in Mechanical Engineering, Advanced Convergence Engineering, Advances in Electrical Engineering and Related Sciences, PetroVietnam Journal,….etc. |