| Floor | Formal Name | Features | Layouts | Max Capacity | Assignable Area (Sq. Meter.) | ||

| 3 |

Sample Processing Laboratory |

Lighting Systerm– Fluorescent; Storage- Closet for Gloves, lab coats, masks, mouth masks, safety goggles; Following equipments: Rough cutting machine, Microwave, SamplePurifying Equipment, Geological sieves, Hydraulic sample press and mold, Sample Mill, Specimen cutting machine, Warming Table/Cross Table, Polishing machine, Pure Water Distiller and Thermostatic tank, Vacuum pouring system |

Lab | 8 | 55 | ||

|

Figure 1: Precision Diamond Saw (Extec, Labcut150) - Rough cutting machine The EXTEC Labcut® 150 Variable Speed Precision Diamond Saw is an attractive, modern styled laboratory instrument designed for precision cutting of a wide variety of materials. Rock samples can be cut with minimal damage and deformation. |

Figure 2: Microwave Digestion system (Aurora-Canada, Transform 680) Using microwave technology to assist with the excavation of samples |

Figure 3: Sample Purifying Equipment This equipment helps rock species more pure before next steps |

|||||

|

Figure 4: Sieve Shaker (Impact Test Equipment, SV005)Geological sieves This equipment is used to determine the particle size distribution of a given sedimentary sample. Lecturer will introduce this equipment to students when they study the course Sedimentology |

Figure 5: Manual 12 Ton SpectroPress (Chemplex Industries, Series 12T) This hydraulic sample press and mold is used in sample preparation for geochemisty analysis (XRD or XRF) |

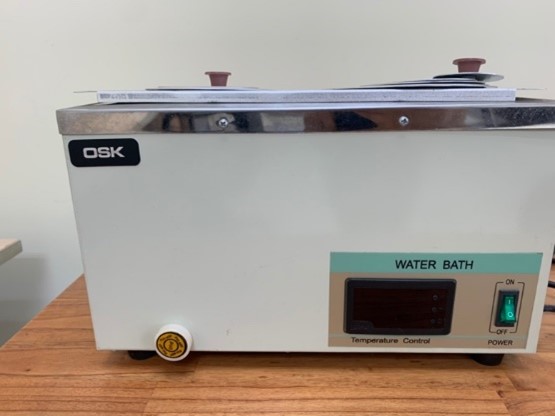

Figure 6: Cross Beater Mills (RETSCH-Germany, SK100)- Sample Mill The sample mill provides highly efficient primary size reduction of heterogeneous material mixes like types of rocks. It is also suitable for grinding soft, medium-hard, elastic or fibrous samples. This mill offers a high level of operational safety and convenience. |

|||||

|

Figure 7: Metallographic Abrasive Cutters (PACE Technologies; MEGA-M250) The MEGA-M250 Saw has been designed for cutting and sectioning moderate sized metallographic materials ranging from soft aluminum metals to hardened tool steels. It is ideal for the metallographic laboratory, as well as for small industrial or production applications. |

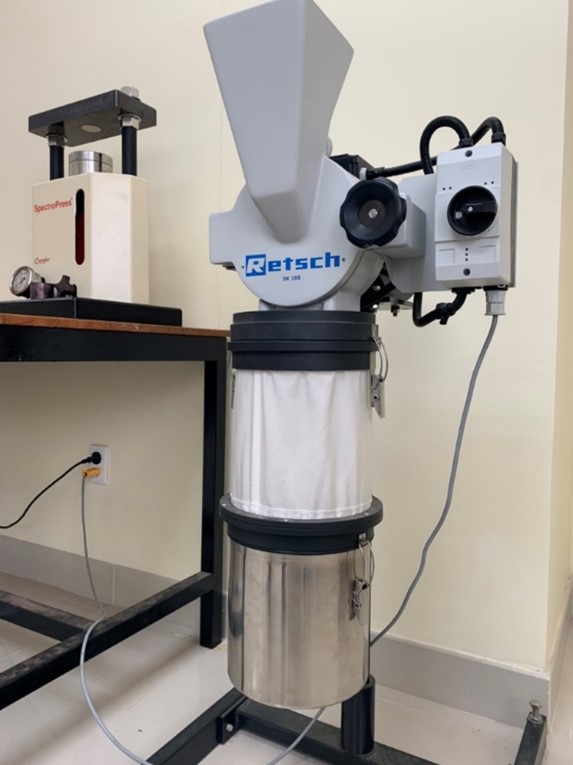

Figure 8: Hotplates (Bibby Stuart _UK, CB300)- Warming Table/Cross Table This equipment has a glass ceramic top which has excellent chemical resistance and allows much higher plate temperature. The temperature ranges from room temperature to 4000C |

Figure 9: Polishing machine The goal of materialographic polishing is to achieve the smoothest possible surface with minimal deformation. This equipment helps the preparation of specimens more complete and more reliable. |

|||||

|

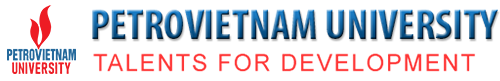

Figure 10: Pure Water Distiller and Thermostatic tank This equipmenthelps to make pure water which is used to wash rock samples before cutting and grinding |

Figure 11: PACE Technologies; LSSA-011- Vacuum Mounting Chamber This system is used to make sure that the thin section without the air inside |

Figure 12: Table for preparing the microscope slides |

|||||

|

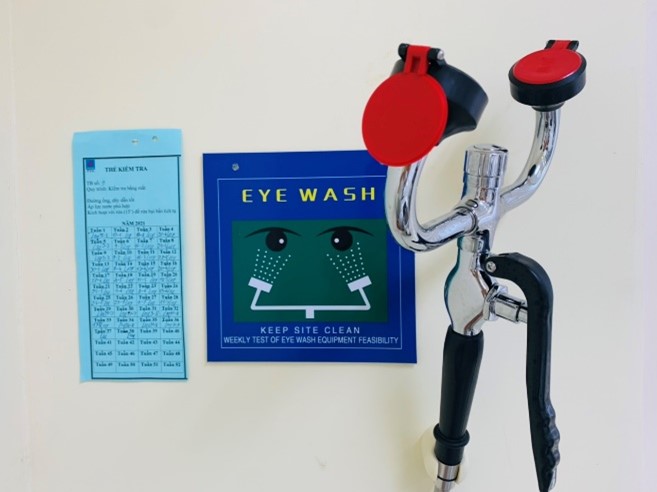

Figure 13: Eye Wash The emergency eyewash nozzle is equipped to wash the eyes in case debris or dust splash into eyes during the process of sample cutting or grinding. |

Figure 14: The entrance of the laboratory |

Figure 15: The lab regulations hang on the wall right next to the entrance door |

|||||